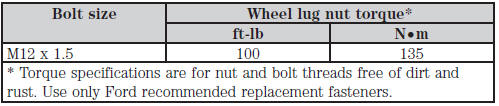

Wheel lug nut torque specifications

WARNING: When a wheel is installed, always remove any corrosion, dirt or foreign materials present on the mounting surfaces of the wheel or the surface of the wheel hub, brake drum or brake disc that contacts the wheel. Ensure that any fasteners that attach the rotor to the hub are secured so they do not interfere with the mounting surfaces of the wheel. Installing wheels without correct metal-to-metal contact at the wheel mounting surfaces can cause the wheel nuts to loosen and the wheel to come off while the vehicle is in motion, resulting in loss of control.

Retighten the lug nuts to the specified torque within 100 miles (160 km) after any wheel disturbance (tire rotation, changing a flat tire, wheel removal, etc.).

Note: Inspect the wheel pilot bore (1) and mounting surface prior to installation. Remove any visible corrosion or loose particles.

See also:

Speed control

With speed control set, you can maintain a set speed without keeping

your foot on the accelerator pedal.

WARNING: Do not use the speed control in heavy traffic or on

roads that are winding, slipp ...

Disposal of airbags and airbag equipped vehicles

For disposal of airbags or airbag equipped vehicles, see your authorized

dealer. Airbags MUST BE disposed of by qualified personnel. ...

System check and vehicle feature customization

Press the SETUP button repeatedly

to cycle the message center through

the following features:

RESET FOR SYSTEM CHECK

When this message appears, press

the RESET button and the message

...